Water-Resistant Innovation: Consumer Electronics Enclosure Design

Learn how we developed an innovative water-resistant enclosure design achieving IPX7 rating while optimizing production efficiency and maintaining aesthetic appeal.

Key Achievements

IPX7

Water Resistance

Immersion up to 1m for 30 mins

15%

Cycle Time

Reduction in production time

8%

Material Cost

Optimization savings

Zero

Field Failures

Since launch

Project Background

A leading consumer electronics manufacturer approached us to develop a water-resistant enclosure for their next-generation portable device. The project required balancing multiple competing requirements:

- IPX7 water resistance rating requirement

- Premium look and feel with minimal seam lines

- Efficient heat dissipation for internal components

- High-volume production capability (500K units/year)

- Cost-effective design for competitive market positioning

Technical Challenges

Water Resistance Design

- Complex geometry requiring multiple seal interfaces

- Port protection while maintaining accessibility

- Material selection for long-term seal integrity

- Testing and validation procedures development

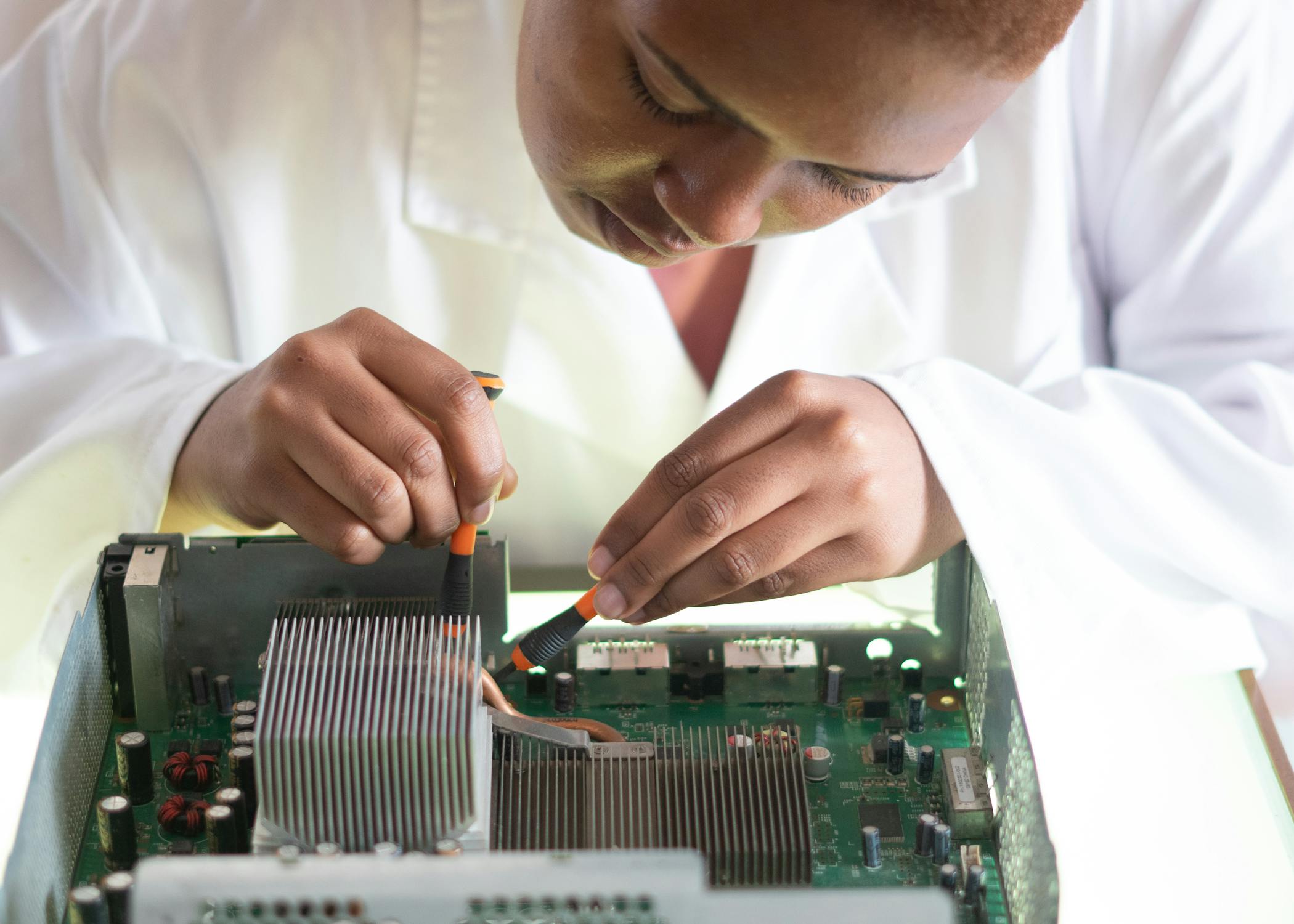

Thermal Management

- Heat dissipation through sealed enclosure

- Thermal interface material selection

- Airflow optimization within constraints

- Temperature monitoring system integration

Manufacturing Considerations

- Multi-shot molding process development

- Assembly automation requirements

- Quality control and testing procedures

- Production cycle time optimization

Solution Development

Sealing Technology

- Dual-shot LSR technology for primary seals

- Integrated snap-fit with secondary sealing

- Port covers with living hinges

- Pressure relief valve integration

Material Selection

- PC/ABS blend for structural components

- TPE overmold for grip and sealing

- Custom LSR formulation for durability

- Thermal interface materials optimization

Manufacturing Process

- Multi-cavity tool design with hot runners

- Automated assembly and testing stations

- In-line seal verification system

- Optimized cycle time through simulation

Implementation & Testing

Rigorous testing and validation procedures were implemented to ensure design success:

- Environmental testing chamber validation

- Accelerated life cycle testing

- Drop and impact resistance verification

- Thermal performance monitoring

- Production line quality control procedures

Results & Impact

The project achieved all key objectives and established new benchmarks:

- Successful IPX7 certification achieved

- 15% reduction in production cycle time

- 8% material cost optimization

- Zero field failures reported since launch

- Positive user feedback on design and durability

"ATI Engineers delivered an exceptional solution that exceeded our expectations. The water-resistant design has become a key differentiator for our product in the market."

Technical Specifications

Detailed specifications of the final design

- Material

- PC/ABS with TPE Overmold

- Wall Thickness

- 1.5mm - 2.2mm

- Seal Design

- Dual-Shot LSR

- Assembly Method

- Snap-Fit with Secondary Seals

- Water Rating

- IPX7 Certified

- Temperature Range

- -20°C to +60°C

- Drop Rating

- MIL-STD-810G, 1.5m

- Production Volume

- 500K units/year

Ready to Waterproof Your Design?

Let's discuss how we can help protect your electronic products.